This series is written by guest blogger, Pamela Cox. Pamela is an expert embroiderer, designer, digitizer and all around wonderful girl! We are so happy to have her contributing to the Sulky Blog!

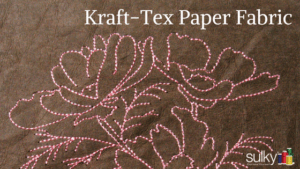

Kraft-Tex™ Paper

All artists relish finding new methods in expressing individual creativity. Machine embroidery is not exempt from craving new inspirational materials. Welcome, Kraft-Tex™, an exciting product certain to stimulate the imagination.

What it is

Kraft-Tex is a paper product that performs like fabric on many levels. Seriously! At least take the time to read about it, because it is amazing!

Available in several colors, Kraft-Tex can be purchased by the roll, bolt, or in sample packages of multiple colors. It seems to be more easily available on the Internet (such as on C&T Publishing), but do check local craft or fabric stores.

Directly out of the package, Kraft-Tex looks and feels like a light-weight, sturdy cardboard. In this original state, Kraft-Tex offers many creative outlets such as block printing, drawing, painting, dying, etc..

Taking Care of Kraft-Tex

Since Kraft-Tex is a natural, plant-based product, much like cotton and linen fibers in cloth, it is WASHABLE! I literally threw several large pieces into a washing machine, electing to use cold water. I then threw it into the dryer, setting it to the next to the highest heat. Pre-washing and drying softens the feel of the paper. Plus, the process gives Kraft-Tex a slightly crinkled texture, resembling leather.

Over time, Kraft-Tex continues to soften, stretch, and mellow with use – which are also leather-like properties.

This product cuts easily, but since it is paper, it will dull needles and scissor edges. So, it is best to designate a rotary cutter blade and needle specifically for working with Kraft-Tex.

Although Kraft-Tex does accept machine stitching, it needs to be treated as a non-forgiving surface. Just like any paper or leather surface, every hole made by a needle or pin will remain…forever! If necessary to secure straight edges while stitching, hold joining sections with clips rather than pins – or at least make sure that the pin holes are within the seam allowance.

Putting it to the Test

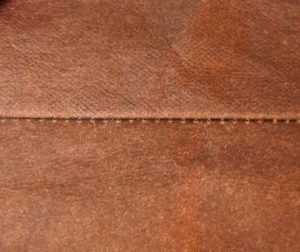

Since Kraft-Tex is advertised to “function like fabric”, I decided to put it to the test by stitching a seam in 100% polyester utility thread with a 90/14 Topstitch Needle, lengthening stitching to 8 stitches per inch. Contrasting thread was used for samples for ease in evaluating tension.

The sewing machine handled the material beautifully. Even seen from the wrong side, the seam looked perfect.

One question was: Would the seam hold under duress or would the perforated paper tear along the seam? Stress was applied to the stitched seam by pulling the paper apart and, I must admit, not too gently! I really pulled at the seam!

Although the holes stretched (not surprising if you knew how hard I pulled) and became a bit more apparent when viewed up close, the stitched seam remained strong, secure, and held no matter how hard I tugged!

So, if nothing else, this material has already proven to be potentially valuable for all kinds of projects – from belts, wallets, coin purses, book covers, luggage tags, tote bags, coupon organizers, bookmarks, and even a key fob! It would also be a valuable resource for Halloween costumes or theater attire, where a “leather” garment/accessory was required, but now could be made at a much lower price point.

What about machine embroidery?

Because I love to machine embroider, the big question for me is… Is this a suitable canvas for machine embroidery?

Considering most modern machines are capable of “machine embroidery” to some extent by employing the often overlooked decorative stitches built into sewing machines, I thought that was a great place to start.

The silky look of Sulky® 40 wt. Rayon provided a striking contrast to the faux leather, while the heavier Sulky 30 wt. Cotton Blendables® – #733-4108 complemented the rugged texture of a Kraft-Tex canvas.

Decorative stitches with space between entry points, or those which re-used the same hole, seemed to work best. Satin-filled stitches shouldn’t be automatically ruled out. However, remember that the closer the needle penetrations are to each other, the weaker the paper foundation will become.

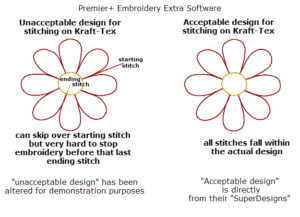

Choosing the proper machine embroidery design for non-forgiving foundations is very important. Not only must every stitch matter by being part of the actual design, needle punctures cannot be too close together or the paper will tear.

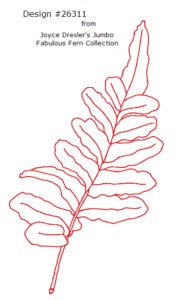

Red-work, stippling, and line designs may prove to be a good choice. However, avoid line designs that include closely placed stitches.

Look at designs specifically digitized for paper or choose a line design that reuses the same holes to boldly define its shape.

You can find the entire Jumbo Fabulous Fern collection here.

Sulky Sticky+™ Stabilizer

Sulky Sticky+™ Stabilizer is the natural choice for Kraft-Tex embroidery since paper cannot be secured directly in the hoop.

Secure Sticky+ in the frame with the release sheet (shiny, gridded paper side) facing up. Gently score the paper with a pin. Peel back the protective paper.

Press Kraft-Tex firmly to the exposed sticky surface.

Never having embroidered on this material, it was important to do a test sample. Fern design #26311 was a perfect choice. The machine was threaded, both top and bobbin, with Sulky 40 wt. Rayon. The machine was put to its slowest speed and a 100/16 Topstitch needle was used.

Knowing that this was just a test, after a short segment of stitching, the large 100/16 Topstitch Needle was changed out to a smaller gauge (90/14 Topstitch) to reduce the size of the penetration holes. The speed of the machine was then increased to its next level. The final experiment switched the rayon thread to Sulky 30 wt. Cotton.

Evaluate your test sample, noting what worked and, if necessary, what didn’t. Label and save test stitching-samples, referring to them for future project input.

The Results

Results: Both Sulky thread types stitched equally well, but each offered a different appeal for the design. The smaller needle gauge (90/14 Topstitch) was preferred.

The testing sample already inspired my first Kraft-Tex project. It will be a tote bag featuring a Poppy design from the Sulky Embroidery Club, stitched in Sulky 30 wt. Cotton, #733-1119. Three fabric prints will be used in a patch-work style bag, accented with additional Kraft-Tex panels. I can’t wait to share this project with you!

I have heard (online) That it is a myth about scissors being dulled by cutting paper. I wouldn’t try it with expensive scissors, but we do cut paper when we use a dress pattern. ????

Wow, this is exciting! Could I use this for the western trapunto design I just purchased?

I would like to respond to both comments at once. I think it is a wise idea to have a good pair of scissors designated to cut fabric only. Personally, I feel paper does dull the cutting edge. I agree that most of us cut through paper when cutting out a pattern, however, purists will actually take the time to first cut out the paper pattern and then lay it on top of the fabric.

As long as the trapunto design is a line design without a lot of closely spaced detail stitches, I bet it will work. Before committing completely, I would like to review the design. As additional support, it might be a good idea to fuse Sulky’s Soft n’ Sheer Extra to the back side of the Kraft-Tex. Good luck. Would love to see a picture!

Does anyone know if Kraft Tex would be appropriate for making a man’s vest?

I think it would make a really cool vest! Kraft-Tex washes and sews like paper so it should hold up just fine. What a cool idea!

Would it be possible to use this as material for an applique – example cutting leaves out and using iron fusing stuff to attach to a base material?

Could you use this material on a die cutting machine like a Sizzix that allows you to cut fabric on it?

could I hand embroider on this material?

I have been using Kraft-Tex for a while for totes but find that it rips at the top of the seam. Any ideas on how to prevent this? I’ve tried minimal backtracking at the top of the seam but it still perforates if it is tugged on

Hi Tish! Try elongating the seam and working with a Microtex needle. Instead of backstitching at the beginning and end of the seam, tie the threads off on the wrong side to knot them. This will prevent unwanted needle holes.

I switch to the needle you recommended but I’m still having tension problems on the back of the fabric. I cannot seem to get the seams tight enough. I’ve made about 100 bags, see my website and NewBluebags.com but I’m still having tension problems. Could it be the thread? I try to heavy duty and now I’m using 100% poly.

I am also wondering if I need an industrial machine. I use a brother XL 2600. I read online that you need an industrial machine to properly sew on Kraft Tex