Linen is the perfect fabric for summer clothing and it is also very popular for home linens and decorative pillows. Let’s not forget accessories such as aprons, purses/totes, guest towels or handkerchiefs. Although the natural flax fiber can be combined with synthetic ones, linen fabric is at its best when 100% natural fibers are used. Linen can be found in a wealth of colors and in a variety of textures: delicately smooth and refined through to a nubby, coarse appearance. How the flax stalks are “processed” and the fibers spun all play a part in the look and weight of the fabric.

Linen fabric should always be pre-washed and dried in the same manner that the finished project will be cared for. Natural fibers will shrink. Press out wrinkles, and often this is easier to do if the fabric is slightly damp. More delicate fibers may require the protection of a pressing cloth.

Embroidery designs need to be chosen in relationship to the weight of the fabric. Lighter linen usually displays best with delicate designs while more dense patterns can be successfully stitched on heavier linens.

Hooping techniques will also differ a bit from one to another. However, as a general rule it is best not to directly hoop linen. Whether the linen is heavier (fabric weave is often more loose due to the thicker, unevenness of the fibers) or lightweight (delicate in nature), directly securing the fabric in the frame may distort the weave. Once released from the frame, the fibers will want to return to their natural places but the embroidery stitching threads will hold them in their “new place”, resulting in possible puckering within the embroidered pattern.

Always hoop the appropriate stabilizer “tight as a drum” in the frame securing the fabric to the top of it by one or more of the following methods:

- Pin fabric, placing pins close to the inside of the hoop’s frame, out of the stitching path.

- Machine baste or “fix” the fabric to the stabilizer, which is a feature found on many embroidery machines.

- Use Sulky® KK 2000™ Temporary Spray Adhesive to lightly spray the stabilizer and smooth the fabric to the sticky surface.

- Use Sulky Sticky+™ Tear-Away Stabilizer on heavier linens.

Let’s get specific about what stabilizer works with which type of linen:

Handkerchief linen (2.75-3 oz.) is a semi-transparent, lightweight, fine fabric.

These wonderful characteristics encourage the selection of delicate embroidery designs, usually found in collections digitized with heirloom or wedding projects in mind. Sulky® Soft ’n Sheer™ is highly recommended to stabilize fabrics of this nature. The stabilizer is just as its name states: lightweight, but strong, soft, and supple; with the added benefit of being sheer. When working with dainty designs and fragile fabrics, you should avoid applying unnecessary stress (like hooping the fabric). Even carefully tearing stabilizer from the back of a project applies some pressure to the fabric and design. Therefore, Soft ’n Sheer™, a cut-away, is recommended. It cuts, trouble-free, yet remains invisible in those very tiny areas which are not only difficult to get at but might just benefit from a bit of extra support:

Hoop Sulky Soft ’n Sheer.

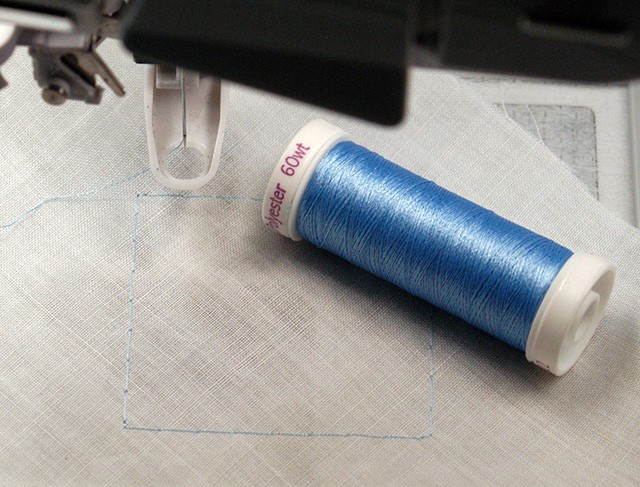

Often the stitching process on fine linen is enhanced by lightly spray-starching the fabric to give it more body. Baste the fabric to the stabilizer, using a small gauge (60/8) Microtex Needle and a fine 60 wt. thread – Sulky® PolyLite™

Change the needle to a 75/11 embroidery needle. Slow the machine speed down (cutting down on friction), allowing a smaller gauge to successfully embroider on finer fabrics.

Stitch out the design.

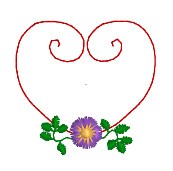

This design is an original digitized on Husqvarna-Viking’s Ultra Premier +™ software

When the embroidery is completed, remove the hoop from the machine. Excess stabilizer and threads need to be removed. Begin by snipping through each bobbin stitch of the “fix or basting box”.

Turn to the right side and gently pull up on the top thread of the basting box.

Cut the majority of the excess stabilizer away. No need to get in too close, but it is always easier working with smaller amounts.

Using sharp, small scissors, cut the stabilizer away from the outside of the design. Then, gently lifting the stabilizer up and away from the stitches, clip close to, but not through, the embroidery.

Since the stabilizer is almost invisible, it can remain inside the heart without compromising the finished product.

However, it is not at all difficult to remove the stabilizer from inside the heart either. Begin by making a small cut in the middle of the heart and snip towards the outside.

Leave the top curls until last. Depending on your skill and comfort level, the stabilizer can remain in that area since Soft ’n Sheer is nearly invisible.

Once the stabilizer and jump threads have been removed…

…press the fabric face down into a thick terry towel.

Medium-weight linen (5.75 oz.) still displays an even, refined weave but is a bit more sturdy and less sheer. Therefore, designs can be heavier and although Soft ’n Sheer™ is still a good choice, it is not the only one. Sulky Tear-Easy™ can easily be hooped and the linen secured to it. Once the embroidery is complete, Tear-Easy can be effortlessly, although carefully, torn away from a more solid embroidery design.

Hoop Sulky® Tear-Easy™.

Baste fabric to stabilizer using a small gauge (70/10) Microtex Needle.

Change needle out to a 75/11 embroidery needle, slowing the machine down. Stitch out the design:

Design shown is from the Sulky Embroidery Club #655, “Flower border” (www.sulkyembclub.com)

When the embroidery is completed, remove the hoop from the machine. Excess stabilizer and threads need to be removed. Sometimes it is easier to remove the “fix box” while the project is still hooped.

Tweezers are often helpful in holding the fine threads while cutting close to, but not through, the thread knots.

Cut the large amount of stabilizer away from the design. Make one clip into the stabilizer to begin the “tearing-away” process.

Working on a hard flat surface, press one finger on top of the threads in the area to be torn, and gently tear the stabilizer from the design.

Sulky Tear-Easy lives up to its name by being very easy to cleanly tear away from the edges of the embroidery.

Even in small areas, the stabilizer is easy to remove.

Press the design face down into a thick terry towel preserving the 3-dimensional effect that we all love in machine embroidery.

Heavy-weight linen (8 oz.) appears coarse because it displays uneven fiber thicknesses, often with “tufts” readily seen. However, it remains soft to the touch. Either Sulky Tear-Easy or Sticky+ would be great. The “sticky” surface would provide additional security with the looser weave.

Hoop Sulky Sticky+ Stabilizer directly in the frame, with the paper side still intact and facing up. Using a pin, score the paper inside the frame. Slide the pin under one corner of the scored paper, and gently pull it up to reveal the sticky surface of the stabilizer.

Knowing that the chosen design is fairly dense, I decided to add additional security in holding the fabric in place by pinning right inside the frame, away from any stitching.

The butterfly design (1181) shown is a free download available to all members of the Sulky Embroidery Club.

Since I’m always looking to make a design “originally special”, I decided to embroider the design by using two threads as opposed to the traditional way of only using one thread. So, I “experimented”:

Sulky 40wt Rayon and Sliver™ Metallic thread, a thin, flat, ribbon-like polyester filament, were both threaded into the sewing machine following the machine’s manual for “twin-needle” threading; with the only difference being that a single needle was used with both threads going through the same eye. In order to reduce friction during the stitching process, a Topstitch Needle (100/16) was used. The stitching speed was reduced to 1/4th of the maximum, as well.

Once completed, the pins were removed, and stabilized fabric was removed from the hoop. Beginning in one corner, the fabric was gently pulled from the sticky surface. “Roll” fabric from each corner towards the center of the embroidery.

The stabilizer will easily tear away from dense edges:

Remove smaller areas, such as inside the antenna separately.

Press the finished project face down into a thick terry towel. (Remember to lower the heat on your iron for metallic threads or use a press cloth.)

And delight in the sparkle as the light catches the beautiful butterfly at different angles! Yum!

Thanks for sharing your talents and experience with us!

The butterfly is beautiful. Thanks for your tips on stabilizers and design choices.

Thank you for sharing this informative article. We are a fine linens business and looking to add additional embroidery options to our linen handkerchiefs. Given we sell the final product, would you recommend the sheer, heat away stabilizer for the finer and lightweight linen?

Pingback: Linen Apron with Embroidery for Mother's Day Gifting - Sulky