Rayon versus Polyester Thread

Rayon versus polyester: which thread to use for machine embroidery?

Crayons, oil paints, water-colors, and even chalk are ways in which an artist expresses creativity.

Almost all of us began our machine embroidery love affair by stitching designs in a 40 wt. Rayon or Polyester Thread. Embroidery supplies and techniques tend to be very personal, and we may have, at one time or another, engaged in a somewhat excitable conversation in defending our choice.

Hopefully, after understanding a bit more about both Rayon and Polyester Thread you will agree that not only is there a place for both threads in machine embroidery, but that it is a must to include both thread types within your own thread collection!

Rayon and Polyester are sometimes both thought of as Synthetic products; those which are “man-made”. This is true of Polyester: “poly” (many) “ester” (a basic organic chemical compound). The product of this chemical chain can be made into a continuous, long filament to produce a smooth, yet very strong thread. This filament can also be cut into predetermined lengths, staple form, and combined with other fibers like a cotton/polyester thread (polyester core covered with cotton).

However, Rayon Thread is a hybrid! It is a mixture of a natural resource, wood pulp, which undergoes an abundant amount of chemical processing. The final filament is referred to as viscose. Many people don’t know that Rayon, sometimes referred to as Viscose, originates from nature! The raw material needed for the production of viscose is cellulose pulp, and the original material for the pulp production is wood.

Cellulose is the natural building material needed by plants for forming their cellular walls. There are only a few wood types where the cellulose develops the properties required for the production of viscose. In most cases, pine or spruce wood, or even well selected deciduous tree types, are used.

The world renowned ENKA plant in Obernburg, Germany produces raw viscose fibers exclusively from these long-chain, consistently high quality cellulose molecules. All Sulky Rayon Threads are made exclusively with ENKA raw fibers, which have been tested and certified to be the highest quality rayon/viscose fibers in the world.

Both Sulky Rayon and Sulky Polyester Threads mirror the reflective qualities of Silk thread, but at a much lower price!

Let’s compare the two types of thread to find our winner!

Many “purists” will state that Polyester Thread always looks like plastic, which is another by-product of basically the same chemical process. However, if the Polyester Thread is of a high quality, such as those found within the Sulky Thread family (PolyDeco™), this thread will beautifully reflect light. Rayon Thread tends to have a luster in its shine, although it sometimes can be difficult to differentiate between a designed stitched in Sulky Rayon and one stitched in Sulky Polyester Thread, especially in photos.

This stitched sample, #1097, Fleur de lis Scrollwork, is available as a free download on Sulky’s Embroidery Club website. It is perfect for quick stitching when deciding on which thread type, weight, or color to use. Stitching a sample provides a true visual, allowing any machine adjustments to be made prior to embroidering a project.

Polyester is slightly stronger than Rayon. However, since both threads are being used to “color in” an embroidery design rather than hold a seam together, strength is a non-issue. And Sulky Rayon Threads have been used on high-speed industrial embroidery machines for over 75 years.

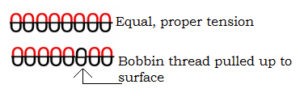

Polyester Thread will stretch before it will break and will wear a needle a little faster than Rayon. Although the tip of the needle dulls by repeatedly penetrating a fabric, friction causes any thread to wear out the eye of the needle. This causes thread to break, fray, and bunch up on itself. If this occurs, sometimes just changing to a new needle solves the problem. This stretch factor is a mixed blessing. It does add some strength, but it can also cause thread pull-ups because of the stretch, and may create tension issues not found with Rayon.

Both threads wash and wear equally well, even in hot water. If an item will be subjected to chlorine bleach or constant sun exposure, then the Polyester Thread is recommended. Having said that, how often is chlorine bleach used on colored fabrics or items with color accents?

When embroidering onto fine fabrics, such as Batiste or Handkerchief Linen, Rayon Thread has a slight advantage over Polyester in that the filament is smoother, softer, and less abrasive on tender skin with a more natural fabric feel.

Embroidered letters, especially complete phrases, will show more detail if stitched in a lighter 60 wt. Polyester thread – Sulky PolyLite™. Switching to this thread for small elements within a design will also allow the finer details to be noticed, as seen on this tea-stained family tree wall hanging:

Even the most expensive sewing machine pulls up an occasional bobbin thread.

Matching top and bobbin thread when embroidering a design does take a bit more stitching time, but it truly is well worth the effort in eliminating these “blips” in our embroidery! Sulky PolyLite is also perfect for this purpose.

Sulky produces both Rayon and Polyester 40 wt. threads in a wide range of colors and shades to include variegated and multi-colors. Both can be purchased in small or larger spool sizes with a convenient snap-end closure, with very little price difference between filament content. And most are available on Jumbo Cones.

So far, it seems like the two threads are totally equal. But there are times when one thread may have a slight edge over another.

Rayon 40 wt. Thread is by far the most popular thread for computerized stitching; especially since most digitizers space their stitches within a design to accept this type of thread/weight. Also, virtually all sewing machines digitize their decorative stitches for 40 wt.

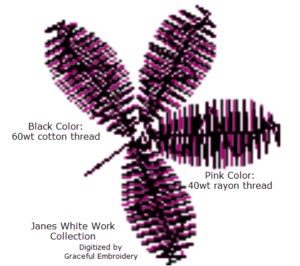

This magnified section of a single element demonstrates that a professional digitizer will space thread placement differently for various thread filament. This does not mean one thread type or weight cannot be successfully substituted for another. Polyester 40 wt. can be readily substituted for Rayon 40 wt. However, if a different weight were to be used, it would be wise to stitch a sample to evaluate results prior to attempting a final project.

The sample stitched is design #130, Mumm with Butterfly, which is available on the Sulky Embroidery Club website. It was digitized to accept Sulky PolyLite, a 60 wt. Polyester thread.

The same design was then stitched in part with Rayon 40 wt. Thread and PolyDeco, which is also a 40 wt. thread, but has a polyester filament. Can you tell which part of the design was stitched in which filament?

When the stitch-outs are compared side-by-side (left, 60 wt. and right, 40 wt.), one design appears denser than the other. The difference in coverage is due to the thread weight, not the thread content. If you could hold this sample, you would feel that the design on the right even feels heavier. Thicker thread is being placed in the same holes that were intended for a lighter thread, making it necessary for the 40 wt. threads to overlap.

The design on the right stitched the outline on the lower large leaf in 40 wt. PolyDeco, while the rest of the design used the finer, 60 wt. PolyLite for the outline. If you can see the difference in the outline, then you will begin to understand how thread weight affects an embroidery design.

As far as reflective appearance…

If you can tell that the butterfly on the right was stitched in 40 wt. PolyDeco while the rest of that design was stitched in 40 wt. Rayon thread, and you have a preference as to which look you like better, then you have come up with your winner!

However, it does look like a draw as far as thread content in reflecting light, with Rayon filament having a slight edge for some applications while Polyester filament has small advantages in others.

There is a definite winner for thread weight! But even that winner changes with types of embroidery currently being stitched.

The real winner is you when the thread on the machine is from Sulky.

Then it is a Win-Win!!

Excellent Article! It is so wonderful to see this information in the Sulky blog. As a Sulky Educator, I like to get this information out in every lecture or event that we do, but to be able to see it in this detail is fantastic! Thank you!

This marvelous comparison of rayon and polyester threads is wonderfully clear and definitely helpful! Thank you and great job, Pamela.

Great article, Pam. Very informative, too. My personal thread cabinet is loaded with all shades of Sulky Polyester and Rayon!

Very good information, I have never used sulky thread, but will be changing to it, I have lot of thread to use up first,

Hi Fran, I wouldn’t wait to “use up my thread” before switching!! Trust me, Sulky thread makes a difference. Use your other thread in bobbins for “like colors” when machine embroidering or when “fixing” your fabric in the hoop or even when marking design placement with hand basting. What’s that saying? “Try it, you’ll like it”? I think you will LOVE Sulky thread!

Pamela Cox

I’m confused by how you labeled your pictures. In the individual pictures you say that the brighter flower is 60wt and the duller flower is 40wt. But the side by side photo you have them switched. Can you clarify which is which? For the Fleur de lis scrollwork design at the top of the article: is the left side done in rayon? I didn’t see a label for this one either. Thanks.

Hi! Sorry for the delayed response. I wanted to make sure we had the right information. I have edited the blog post to what it is supposed to say. The one on the left is the 60 wt. and the right is the 40 wt. I’ve also added another photo of the scroll-work design to show the threads used for each design. Sorry about that! Thanks for pointing it out to us! Happy Sewing!

I thought that rayon thread could not stand as much heat as polyester and might melt under an iron. Is this true? (Heat was not addressed in your comparison.)

It is not. It’s the opposite. Rayon can take more heat than polyester. This is a caution to all of us who use polyester in the bobbin, too. The wrong side with the polyester thread, can melt long before the heat would affect the rayon top thread.

Rayon may not stand as much heat as cotton thread, though. In all my years of being very careless with my iron (always having it set on cotton), I have never, ever damaged the rayon thread. However, I have melted polyester on a rayon setting. But irons vary tremendously, as you know.

Patti Lee

Sulky Customer Care