Sewing Machine Maintenance

A Sewing Spa Day

Sewing machine maintenance is an essential part of sewing. Eric Drexler, National Sulky Educator and sewing machine technician, shares his recommendations for sewing machine maintenance and why we should get our machines in tip-top shape for all of our 2021 makes.

from Eric:

I have been repairing sewing machines for over 35 years and I’ve seen a lot of crazy things.

A sewing machine is in fact, a machine. Machines need to be serviced. More often is better. Not only do they need to be cleaned and oiled on the inside, but also inspected for damage and to make mechanical adjustments.

The following are some of the things I see when the covers come off.

DIRTY MACHINES

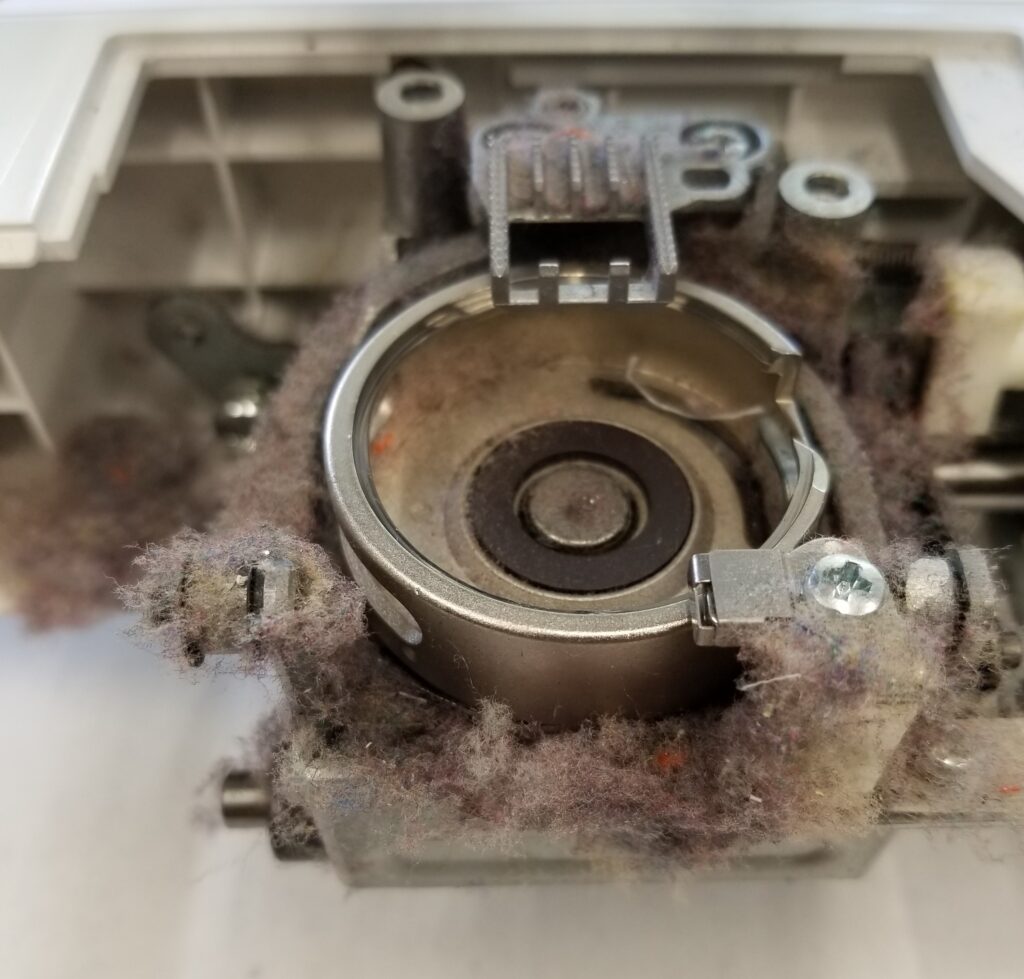

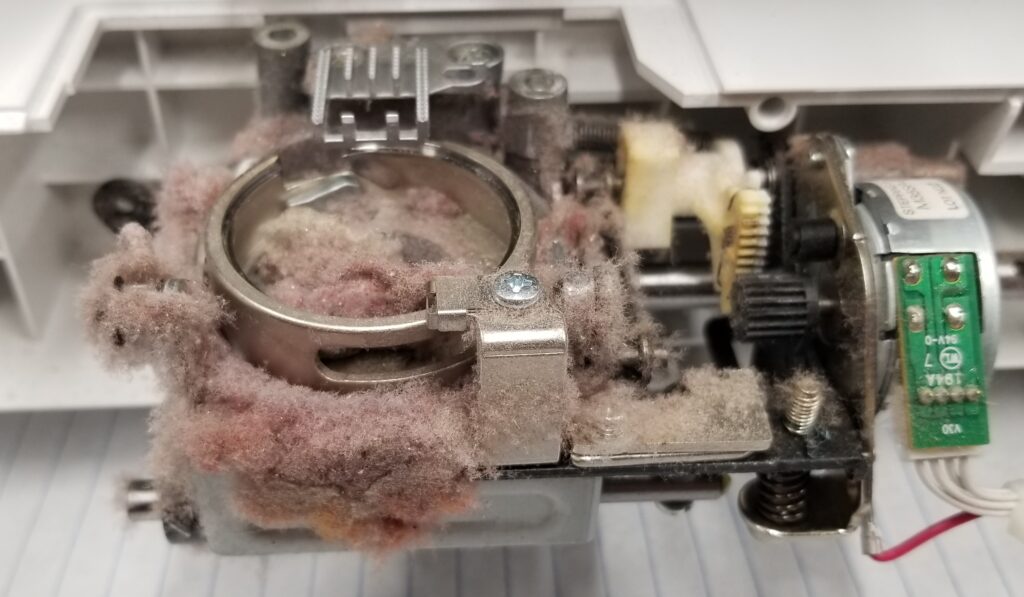

Even if you clean the outside of your machine regularly, part of sewing machine maintenance is cleaning the inside–the parts you can’t reach.

Today’s machines are nearly impossible for the end user to service. In most cases you can take off the needle plate to clean this area, but stuff migrates throughout the closed housing that you can’t see by just looking. Be sure to take your machine to a reputable technician or back to the dealer where it was purchased for regular sewing machine maintenance appointments.

To prevent real problems, never blow away lint. Some of it may come out, but a LOT goes further in.

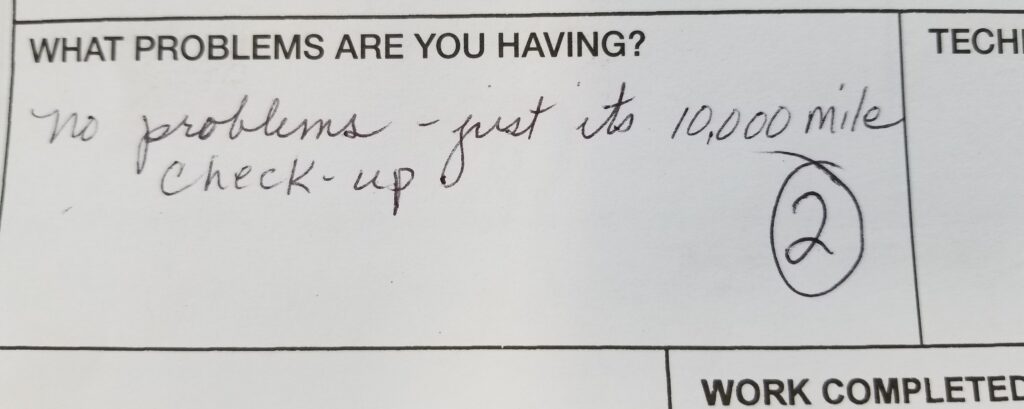

Remove the needle plate and clean out as much lint as possible. Make sure to clean between the feed dogs. In this case, the customer comment was, “Doesn’t feed”. With this many layers of fuzz build up, the bobbin thread couldn’t come up through the plate.

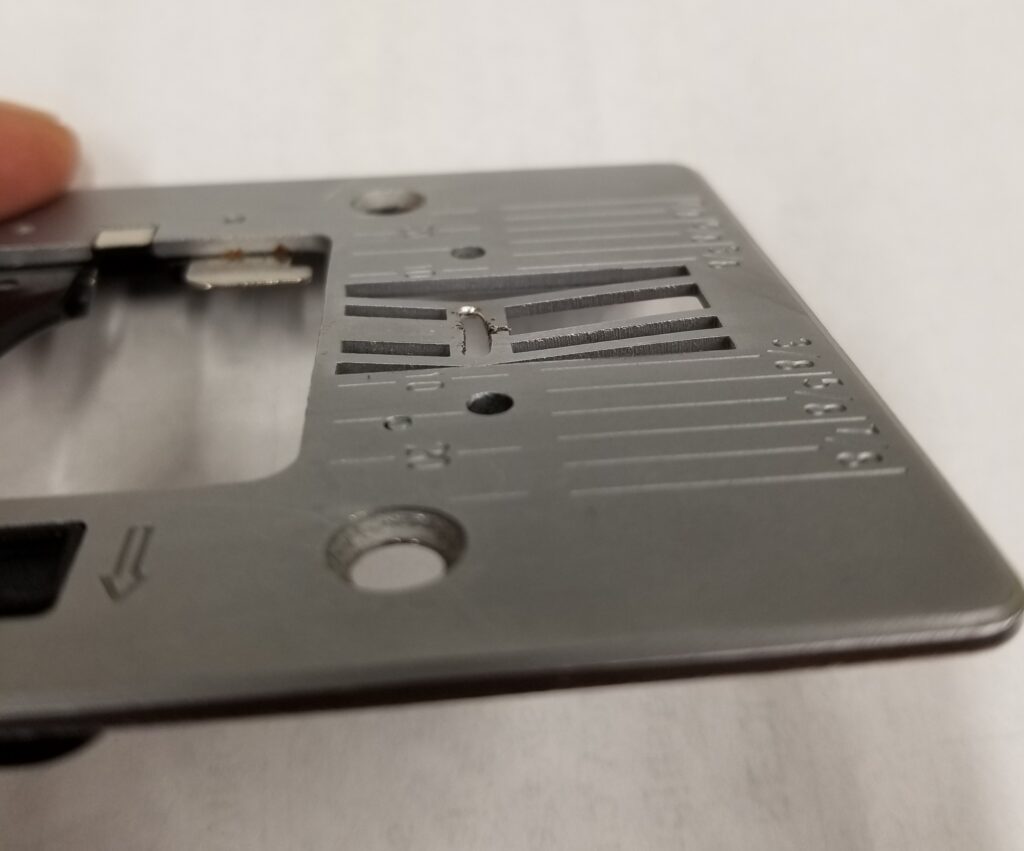

NEEDLE PLATE MAINTENANCE

Always inspect the needle plate. Damage can occur if the wrong size needle is used and deflects when going through fabric that’s too heavy. Another cause I’ve seen from years of watching hundreds of customers sew, is because they PULL the fabric through or hold it back. Pulling will drag the needle into the plate, and the needle can also hit the hook and/or bobbin case.

This one came in saying “It wouldn’t feed.”

BOBBIN MAINTENANCE

Top-loading bobbin cases also sustain damage and need replacing. This is usually caused by not threading the upper thread properly. The most common is not threading the take-up lever.

SEWING MACHINE PRESSER FOOT

Wear on the bottom of the presser foot will slow the flow of the fabric. These grooves are “cut” into the sole of the foot over the years as we run the machine without fabric. Rather than changing how you sew, replace the presser foot when the chrome wears off for the best performance.

THREAD BUILD-UP

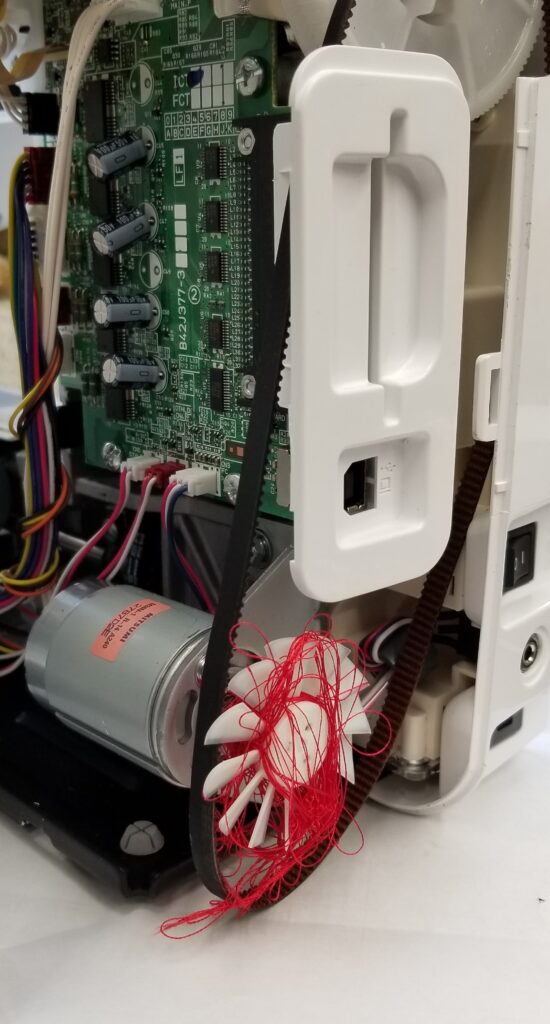

Thread has a unique way of working its way into the strangest places. All of these are bad and can cause the machine to slow down or cause damage.

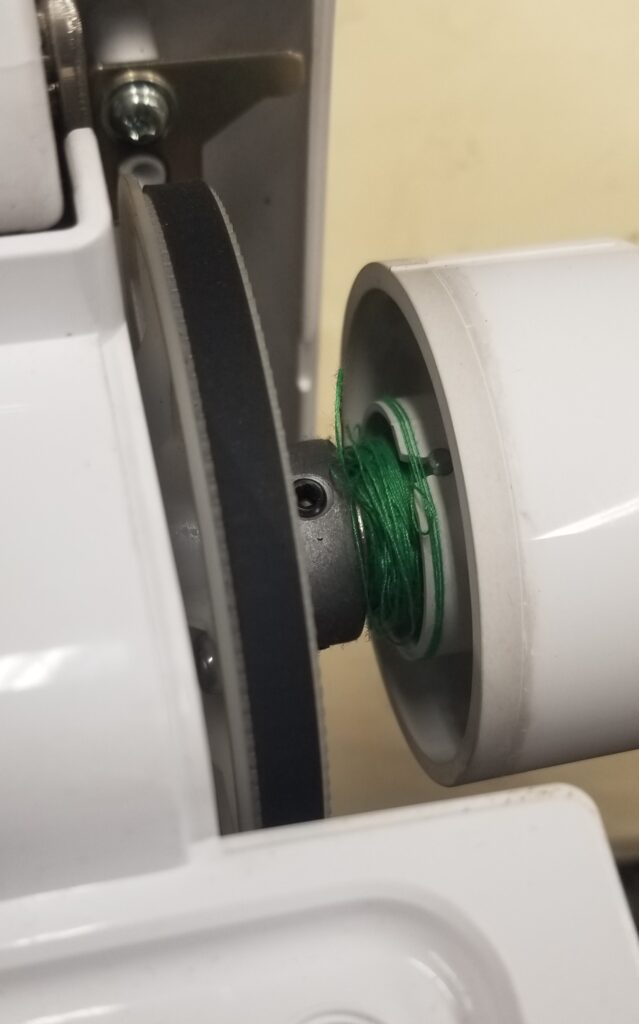

Notice how the thread caught under this bobbin winder isn’t visible when looking at the machine with the cover on.

Thread can also get trapped in the handwheel without realizing it. If you store thread spools next to or behind your machine, check to make sure the thread ends are secure in the spool so they don’t migrate to any mechanical parts of the sewing machine.

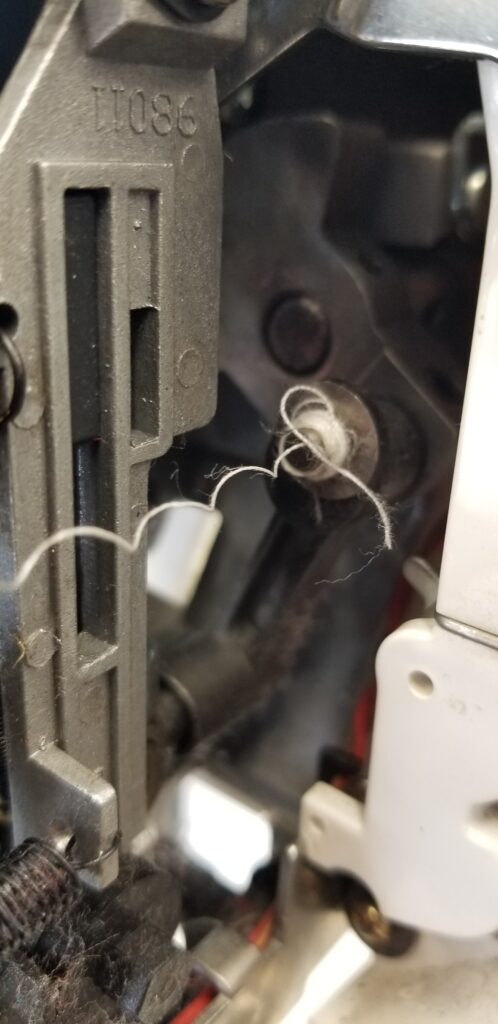

If you’ve ever had a thread breakage during threading or sewing and you weren’t able to find it all, it may have left behind remnants in the tension discs. Over time (or even immediately) this will prevent other threads from nesting in the discs as intended, resulting in skipped stitches, loose stitches or stitches that are too tight.

Thread in the take-up lever is not obvious to the naked eye. This can cause damage and poor stitch quality.

Even worse is if the thread is wrapped in the motor. Be aware of the thread ends if you store thread beside your machine or on the bobbin winder (or anywhere else that is not a Sulky Slimline container!).

SEWING MACHINE MAINTENANCE “RULES”

Change the needle in your machine after every 6 hours of sewing, or with every new project. Grab assorted Organ Needles to always have new needles at your fingertips.

Thread the machine properly, following the manufacturer’s instructions. Many times people purchase a new machine and think they know how to thread it without reading the manual. Improper threading can make the thread “CUT” into the cover. This is very bad and will cause serious damage to the thread and continue to cut into the machine.

As we embark into a new year full of possibilities and new projects to tackle, make sure to give your sewing machine a spa day and take it in for service. It deserves to be pampered, just like you do!

This is all great advice. Thanks for sharing it. Happy Holidays to all of you at Sulky.

Really scary photos, but also very interesting!