Sulky’s 30th Anniversary: The History of Sulky Solvy

To continue our celebration of Sulky’s 30th anniversary, we spoke with Fred and Joyce Drexler, the co-founders of Sulky of America, to learn how Solvy got its start here at Sulky…

The History of Solvy® in the United States really began 34 years ago at the Bobbin Show in the World Congress Trade Center in Atlanta. This immense trade show showcased every imaginable type of equipment and product that Ready-To-Wear and Commercial Embroidery Manufacturers needed or wanted, to be able to manufacture clothing and do large-scale embroidery jobs. Attendees came from all over the world and walked miles of aisles to check out all of the latest products.

When Joyce and I heard about this show, we decided to attend in 1983 to see if we could find any products that we felt would be appropriate for the home sewing market. It had to be fate that our future German partners also decided to exhibit at this show for their very first time and, more importantly, to introduce to the world their new water-soluble stabilizer product called Solvy.

When Joyce first saw Solvy she became very excited about all of its possible uses in the Speed Stitch™ kits that she was planning to produce. These included Cut Work, Battenberg Lace, and Monogramming. At the time, Cut Work was done very laboriously using the plastic film that covered your clothes when you got them back from the dry cleaners. Solvy made the process light years easier and faster. And thus a star was born and a relationship was begun that would lead to the creation of Sulky® of America 4 years later!

Our company, Speed Stitch, immediately began packaging and marketing Solvy under the trademarked name, Wash Away™. Over the next 10 years, we sold it to a dozen different distributors who sold it to thousands of retail stores across the United States and Canada.

The Start of Sulky Solvy

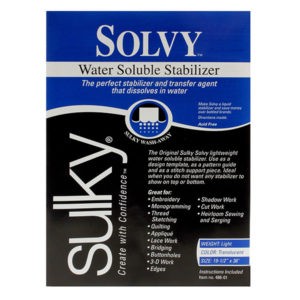

In 1989, Sulky of America acquired the licensing rights to the trademarked name, Solvy, from our German partners, and Sulky introduced it, along with Totally Stable™, to Sulky retailers and consumers.

By then Joyce had found numerous other uses for Solvy including: using it as a design template; as a pattern guide; to support stitches on the edge of fabric; as a topper on napped fabrics like towels to keep the loops or piles from poking through; to keep stitches from getting lost in any fabric; for bridging and buttonholes; to enhance the clarity of fine lettering and detail stitching; and to make your own liquid, brush-on stabilizer, to name a few.

Super Solvy

In the early years, we discovered that you could make Solvy twice as thick by fusing 2 layers together with a warm, dry iron so it would be heavy enough to support free-motion embroidery stitching or lace making. A short time later, we introduced Sulky Super Solvy™, which was twice as thick as the original Sulky Solvy, so you didn’t have to fuse layers together.

Ultra Solvy

As consumers wanted to make increasingly larger and more complex embroideries and laces, they were fusing 2 layers of Super Solvy together to be able to stitch them. Eventually, we introduced Sulky Ultra Solvy™, which is a very heavy water-soluble film that is 4 times as heavy as the original Solvy, again to avoid having to fuse layers together. Ultra Solvy has all the firmness that is required when creating stand-alone Thread Lace, Cut Work, Battenberg Lace, Digitized Lace, Hoop-less Machine Embroidery, or Free-Motion Embroidery.

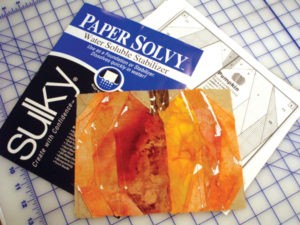

Paper Solvy

When Paper Piecing became popular, we introduced Sulky Paper Solvy™ to make this technique much, much easier. By inserting a pre-cut 8 ½” x 11” piece into a copier, ink-jet printer or bubble-jet printer, you can print any design directly onto the Paper Solvy.

Fabri-Solvy

Several years ago we introduced Sulky Fabri-Solvy™, which has the firmness, strength and feel of fabric. It is non-woven so it doesn’t stretch in any direction while having the strength and quality to support stand-alone Computer Embroideries, Cut Work, Lace-Making, Free-Motion Embroidery, and Turned Appliques. When we added a sticky back and release sheet to Fabri-Solvy, we created, by far, the easiest way to transfer a pattern using your printer or copier so you could stitch over it by hand or machine, then easily remove the remnants. It is also perfect for printing quilting templates. This product is marketed under 3 distinct names for 3 distinct markets.

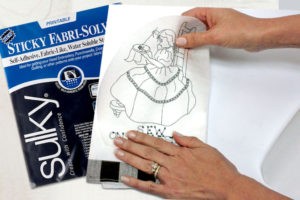

When we added a sticky back and release sheet to Fabri-Solvy, we created, by far, the easiest way to transfer a pattern using your printer or copier so you could stitch over it by hand or machine, then easily remove the remnants. It is also perfect for printing quilting templates. This product is marketed under 3 distinct names for 3 distinct markets.

- Sticky Fabri-Solvy

Because home sewing, quilting and embroidery consumers knew and loved Fabri-Solvy, it seemed intuitive to originally name the sticky-backed version Sticky Fabri-Solvy™.

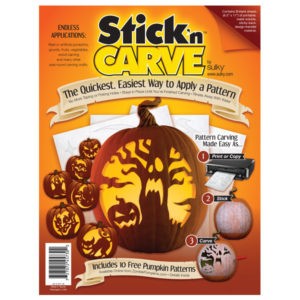

- Stick ‘n Carve

Then, along came a culinary expert and professional carver of watermelons who raved about how much easier it was for him to get a design in place on watermelons for him to carve.  Through extensive testing we found that to also be the case for Pumpkins as well as other fruits and vegetables, wood, rubber stamps and much more. And so, Sulky Stick ‘n Carve™ became the second distinctive name for this product.

Through extensive testing we found that to also be the case for Pumpkins as well as other fruits and vegetables, wood, rubber stamps and much more. And so, Sulky Stick ‘n Carve™ became the second distinctive name for this product.

- Stick ‘n Stitch

With ever-increasing numbers of consumers discovering and loving the beauty and convenience of using Sulky 12 wt. Cotton Petites for hand sewing rather than floss, we realized that getting designs in place to stitch was a big component.

Since neither of our other two names for this product really spoke to this market about how easily this product made it to get their design in place we created the third name, Sulky Stick ‘n Stitch™.

We never would have imagined 34 years ago what an important role Solvy would play in the history and growth of Sulky of America.