It is made from ENKA Viscose, which is 100% biodegradable; and the availability of the renewable resource, wood, is virtually unlimited.

The raw material needed for the production of viscose is cellulose pulp, and the original material for the pulp production is wood.Cellulose is the natural building material needed by plants for forming their cellular walls. There are only a few wood types where the cellulose develops the properties required for the production of viscose. In most cases, pine or spruce wood, or even well selected deciduous tree types, are used.

The raw material needed for the production of viscose is cellulose pulp, and the original material for the pulp production is wood.Cellulose is the natural building material needed by plants for forming their cellular walls. There are only a few wood types where the cellulose develops the properties required for the production of viscose. In most cases, pine or spruce wood, or even well selected deciduous tree types, are used.

One of the special features of cellulose is that the molecules are connected with each other in chains, and the length of the chain is critical for producing the highest quality raw viscose fibers. Long-chain, consistently high quality cellulose molecules are absolutely necessary for reprocessing cellulose into a perfect viscose product.

One of the special features of cellulose is that the molecules are connected with each other in chains, and the length of the chain is critical for producing the highest quality raw viscose fibers. Long-chain, consistently high quality cellulose molecules are absolutely necessary for reprocessing cellulose into a perfect viscose product.

The world renowned ENKA plant in Obernburg, Germany guarantees that the majority of the needed raw materials to produce the highest quality Viscose in the world can be almost completely reprocessed and recycled into the production process (closed loop). Any additional wastewater and exhaust air is treated and cleaned with due diligence and and according to strict European environmental regulations (among the strictest in the world). That’s why Sulky Rayon Threads are made exclusively with ENKA raw fibers, which have been tested and certified to be the highest quality rayon/viscose fibers in the world!

The world renowned ENKA plant in Obernburg, Germany guarantees that the majority of the needed raw materials to produce the highest quality Viscose in the world can be almost completely reprocessed and recycled into the production process (closed loop). Any additional wastewater and exhaust air is treated and cleaned with due diligence and and according to strict European environmental regulations (among the strictest in the world). That’s why Sulky Rayon Threads are made exclusively with ENKA raw fibers, which have been tested and certified to be the highest quality rayon/viscose fibers in the world!

The trees that ENKA’s raw viscose fibers are produced from are substantially and consistently better because ENKA strictly controls every working step from cultivating the right trees on plantations with optimal climatic and geologic conditions, to reprocessing only the highest quality long-chain cellulose fibers. Cultivating trees on carefully controlled plantations is the agricultural use of a permanently regenerating source – wood.

Because ENKA knows that only consistently high quality, long-chain cellulose guarantees a perfect viscose product, they make sure that every single step is subject to their strict oversight, from selecting the seeds from healthy trees to keeping a data sheet on which the entire life story of the tree is written down.

Because ENKA knows that only consistently high quality, long-chain cellulose guarantees a perfect viscose product, they make sure that every single step is subject to their strict oversight, from selecting the seeds from healthy trees to keeping a data sheet on which the entire life story of the tree is written down.

Furthermore, the growing speed, ground and climatic conditions play an important role. It takes about 20 years until each individual tree has the inner structure and ripeness to meet ENKA’s high quality demands!

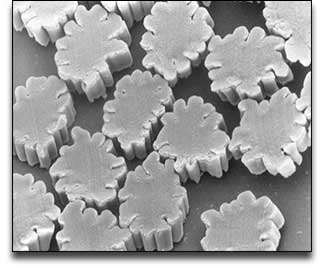

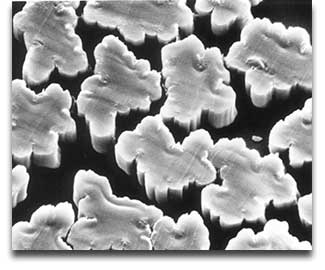

That’s why you experience less breakage with Sulky/ENKA threads even when using high-speed embroidery machines. And why everything you make using Sulky/ENKA threads lasts longer and looks better years from now. Granted, all this extra quality and care may not be apparent when you’re just looking at a 40 wt. rayon thread with the naked eye, but put Sulky/ENKA fibers, along with any others, under a microscope and you’ll see what we’re talking about.

That’s why you experience less breakage with Sulky/ENKA threads even when using high-speed embroidery machines. And why everything you make using Sulky/ENKA threads lasts longer and looks better years from now. Granted, all this extra quality and care may not be apparent when you’re just looking at a 40 wt. rayon thread with the naked eye, but put Sulky/ENKA fibers, along with any others, under a microscope and you’ll see what we’re talking about.

So what does all this mean to you?

Not only does it mean that you can feel good about buying and using Sulky Rayon because it is sustainably sourced and processed, but it also means the thread itself is going to produce better results! Because ENKA fibers have a more even form and structure, they can be dyed more evenly. ENKA fibers also have more perfect optical refraction and cleanness of yarn to make Sulky Rayon threads appear glossier and more brilliant. That’s why embroidery connoisseurs prefer the softer, warmer, more natural look of Sulky Rayon Thread. It’s no wonder Sulky 40 wt. Rayon Threads are the strongest, most brilliant rayon threads available.

To celebrate Earth Day and to highlight our Eco-Friendly Sulky Rayon Thread, we are offering 25% off all of our Sulky 40 Wt. Rayon Thread!

Thank you for this informative information concerning the Sulky thread, this was new to me. I do use this thread, after reading this, I’ll tend to use this thread more.

This is great information and I also use Sulky thread. Sulky has lots of colors to choose from and they sew out beautifully. I like the size of thier spools. It means I can have more colors in my thread stash.

What a pleasant, enthusiastic, and informative article about your marvelous thread! The cross sections of Sulky vs. those of Asian viscose show it all! Small wonder that we get better results with Sulky. My engineer father taught me to sew, and he emphasized, “Sissy, you need to have the right tools and the right materials to result in the right product!” He was correct, a thousand times over.

I’ll certainly keep stitching with Sulky!

Pushing Rayon thread as earth friendly is deceptive. Yes it comes from nature and yes it is biodegradable. What happens in between is a horror story. Due to the toxic chemicals used in production it is hardly considered earth friendly. To the best of my knowledge rayon is no longer produced in the US because there is no acceptable way to dispose of the toxic waste produced. Port Angeles, WA was once a major producer of wood pulp (basic ingredient in rayon production). It is now a toxic waste cleanup site. If you are interested in the “rest of the story” Google rayon or health hazards related to rayon production and see for yourself how dangerous rayon is to the earth.

While I cannot comment on the manufacturing processes used by those that were in the United States years ago, the stringent European standards and sustainability practices of Enka are in a completely different league. This link on Enka’s website is especially enlightening along with several other links on their site which delve into each component of sustainability in more depth. http://www.enka.de/nachhaltigkeit_1_en.php

Thank you for sharing your thoughts and concerns with us.

Sulky has been my go to for most machine embroidery. I only use Poly for items that will be used outside in the bright sunlight (when we have bright sunlight, that is…LOL).